(Ecns.cn) – The Wuhan Iron and Steel Corporation's (WISCO) plan to build pig farms and "urban modern service centers" was confirmed by Deng Qilin, general manager of the company and deputy to the National People's Congress, on March 7 during the ongoing "two sessions".

As outlined by WISCO's business plan for 2012, the company will invest 39 billion yuan (US$6.2 billion) in non-steel related industries this year, including wine production, vegetable planting and pig farming, as well as logistics by providing services to urban residents, said Deng.

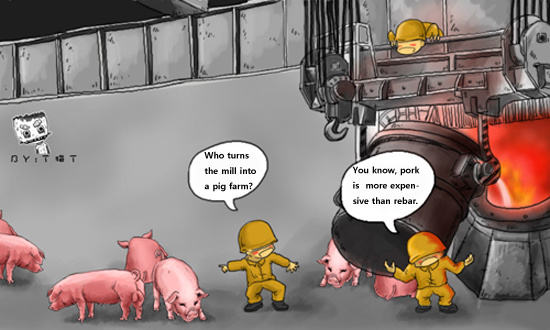

Deng noted that a kilogram of rebar is now worth just a quarter of a kilogram of pork. And for the company's pig farms, the yearly goal is a 10,000 head capacity, which is expected to bring about large profits.

WISCO's new investment plan has sparked debate among steel industry watchers and the general public, but Deng explained that profit margins in the steel industry are becoming ever thinner, so the company must diversify its development plan to make increased profits.

In 2011, WISCO saw annual sales fall to 230 billion yuan and profits to 3 billion yuan, due to a lack of iron ore resources and an increase in distribution costs; not surprisingly, the steelmaker reaped over 60 percent of its earnings from non-steel businesses last year.

Overcapacity and low profit margin

By the end of 2010, China had shut down all steelmakers with blast furnaces smaller than 400 cubic meters, a push to reduce overcapacity in the steel industry after seeing an excess of 170 million tons of steel production in 2009, noted China Daily.

However, according to a report released by the People's Bank of China (PBC), excess capacity remained an outstanding problem in the domestic steel industry last year.

The nation had around 800 million tons of steel production capacity in 2011, while consuming only 650 million tons, said Zhu Jimin, head of the China Iron and Steel Association (CISA) and also chairman of Beijing-based Shougang Group, one of the country's largest iron and steel companies.

Zhu Jimin predicted that for the time being, China can consume at most 750 million tons of steel every year, and that the problem of overcapacity has plagued the whole industry, with an increasing number of steelmakers losing money.

Due to the gradual release of steel capacity and slowing of downstream demand, steel prices are becoming more volatile. In late 2011, the steel price index compiled by CISA declined by 6.11 percent year-on-year. By category, the long product index was down by 6.13 percent and the flat-rolled index was down by 6.61 percent, according to the PBC report.

In January 2012, China's 77 largest steelmakers rolled out 246.69 billion yuan (US$39.1 billion) worth of steel products and sold 260.35 billion yuan (US$41.3 billion) worth of goods, down 4.57 percent and 8.47 percent respectively from a year ago, a source from the CISA said.

The steel industry reported a net loss of 2.18 billion yuan (US$345.8 million) in January, with 12 of the largest 29 mills (each with annual capacity of five million tons or above) operating in the red, the source added.

For or against

For WISCO, such problems have brought it to a critical moment to reconsider the way it uses State assets. With different programs launched for non-steel businesses, Deng Qilin has been blasted by many for being too irrational and reckless during tough times.

However, Deng is determined and confident about the plan, and believes that reform or transformation of the current corporate structure is quite necessary, since the steel industry will continue to earn low profits or even experience losses in the near future.

With a sense of innovation, WISCO has extended its resource supply chain and product chain and updated its corporate technology. For example, in February it started a project of intensive processing in Wuhan for recycling, as well as for new products used in the production of mascara and tires.

Facing objections to the steelmaker's plan for raising pigs, Deng said last year's experience in non-steel businesses proved very successful and he would continue to push the transition.

On this issue, an online survey conducted by People's Daily Online showed that 54.3 percent of 3,120 respondents support WISCO as they think the steelmaker is acutely aware of the future market, 28.2 percent disagree with the plan because the company is ignorant of the profession, while 14.6 percent claim that WISCO is using the government's money to unfairly compete with privately-owned businesses.

Dilemma of state-owned enterprises

In fact, other steelmakers such as China's Baosteel have also achieved success in non-steel operations. Last year, non-steel fields contributed 50 percent to the company's total profit.

Yet some say that without good returns from investments in their own businesses (such as steel manufacturing), the transition across industries entails a wasteful use of capital and technology, which is a common problem that haunts state-owned enterprises (SOEs).

To survive economic development, it is inevitable that SOEs must carry out reforms and become more competitive in the open market. They must figure out measures to recalibrate their access to public resources, introduce modern corporate governance, extend product chains and implement ownership diversification where necessary.

In the steel industry, WISCO is marching at the frontline. In three years, the leading steelmaker will achieve profitability in its non-steel businesses in the amount of 110 billion yuan, about 30 percent of its total profits. And judging from the current situation, momentum will only continue to build behind such reforms.

Copyright ©1999-2011 Chinanews.com. All rights reserved.

Reproduction in whole or in part without permission is prohibited.